Cooling Capacity Range: 559kW~1677kW

Chilled water outlet temperature: 5~20℃

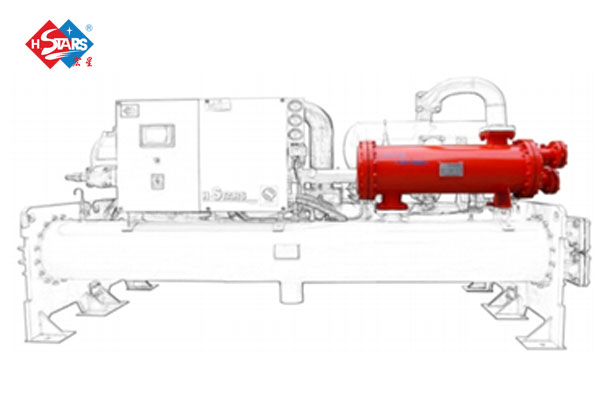

Water-cooled Magnetic Oil Free Centrifugal Chiller with Heat Recovery

H.Stars 50STD Magnetic Oil Free Centrifugal Chiller with heat recovery has two series: “Magnetic Oil Free Centrifugal Water-Cooled Chiller with heat recovery” and “Magnetic Oil Free Centrifugal Air-Cooled Chiller with heat recovery”. 8 standard specifications with Cooling Capacity range from 420 - 7800kw, Lowest outlet chilled water temperature is 5℃. Customized service available base on client requirement, such as Anti-corrosion sea water chiller with various power supply. Besides, the hot free water temperature created by the heat recovery device can reach 45-55℃.

Product features and functions:

1)Adopts high-integration single-chip microcomputer which greatly improves the anti-interference ability of the system.

2)The HMI directly displays the fault content, and cooperates with the simple operation interface to timely feedback various maintenance information.

3)The unit control system can be connected to the user's central control system (BMS), so the customer can monitor the chiller operation at any time.

4)Over-voltage, under-voltage, three-phase unbalance, and lack phase protection are applied to the external power supply system.

Main component:

1) Danfoss compressor (below 450RT)

| 50STD series Magnetic Oil Free Water-cooled Centrifugal Chiller technical | ||||||||||||||||

| Refrigerant:R134a | Power supply:380V-3N-50/60Hz | |||||||||||||||

| Model | Nominal cooling capacity | Input power | Energy control % | Refrigerant charge kg | Cindenser | Evaporator | Running noise dB(A) |

Machine weight kg |

Running weight kg |

|||||||

| kW | USRT | kW | Inlet pipe diameterin | Water flowm3/h | Maximum pressure in the water side MPa | Water pressure drop | Inlet pipe diameterin | Water flowm3/h | Maximum pressure in the water side MPa | Water pressure drop kPa | ||||||

| 50STD-150F2 | 559 | 159 | 95 | 10~100%,DC VFD adjustment | 250 | 5″ | 112 | 1 | 68 | 5″ | 96 | 1 | 68 | 68 | 2430 | 2930 |

| 50STD-300F2 | 1117 | 318 | 190 | 450 | 6″ | 225 | 1 | 70 | 6″ | 192 | 1 | 70 | 69 | 4600 | 5100 | |

| 50STD-450F2 | 1575 | 448 | 242 | 675 | 8″ | 312 | 1 | 74 | 8″ | 271 | 1 | 74 | 74 | 11000 | 11500 | |

| 50STD-900F2 | 3150 | 896 | 484 | 1350 | 10″ | 625 | 1 | 76 | 10″ | 542 | 1 | 76 | 76 | 19000 | 19500 | |

| 50STD-1350F2 | 4725 | 1343 | 726 | 2000 | 12″ | 937 | 1 | 76 | 12″ | 813 | 1 | 76 | 78 | 27000 | 27500 | |

| 50STD-1800F2 | 6300 | 1791 | 968 | 2700 | 14″ | 1250 | 1 | 78 | 14″ | 1083 | 1 | 78 | 80 | 35000 | 35500 | |

| 50STD-2250F2 | 7875 | 2239 | 1210 | 3350 | 16″ | 1562 | 1 | 78 | 16″ | 1354 | 1 | 78 | 82 | 43000 | 43500 | |

Note:

1. Nominal cooling capacity reference:evaporator inlert and outlet water temperature 12°C /7°C,condensor inlet and outlet water temperature 30°C - 35°C; fouling factor 0.088 ㎡ .°C/ KW;

2. Chilled water temperature range: 5-20°C;

3. Cooling water temperature range:15-40°C;

4.Specifications and dimensions improvement will be adjusted without notice.

Control center:

1)It is equipped with a 10 inch display.

2)Built in electronic expansion valve drive module to ensure more accurate liquid supply.

3)Three phase voltage and current are displayed timely and highly integrated with the controller

4)The unit can be connected to each other to form module control,group control or single control freely switch to each control mode.

5)The chiller has built in more than 30 protections functions to provide comprehensive protection for the safe operation of the unit.

6)The chiller has advanced multi-surge function,which combines prevention,control and alarm to make the unit meet the customer's cooling capacity within the safe operation range.

Heat Recovery Technology:

Heat recovery technology is to recycle part of or all of the heat capacity produced during the refrigeration process by heat recovery unit to provide customers free hot water from 45℃ to 55℃,which is suitable for hotel,hospital,school and other places of large public institutions. Friendly environmentally and energy saving.

Development and advantage for heat recovery technology of H.Stars:

H.Stars Group has been engaged in research and practice of heat recovery technology and application for a long period of time (the first company awarded with heat recovery patent) and has accumulated a lot of experience in heat recovery and utilization and own a national patent of heat recovery.

Free hot water supplied all year around,cost and energy saving,it can reduces the heat pollution to the environment caused by condensation heat from the chiller largely.

Heat recovery specification:

| Model | 30% Heat recovery | 100% Heat recovery | ||

| Model of heat recovery unit | Heat recovery capacity (Kw) | Model of heat recovery unit | Heat recovery capacity (Kw) | |

| 50STD-120AP2 | UHR035A | 120 | UHR120A | 400 |

| 50STD-150F2 | UHR045A | 150 | UHR150A | 500 |

| 50STD-300F2 | UHR090A | 300 | UHR300A | 1000 |

| 50STD-450F2 | UHR135A | 450 | UHR450A | 1500 |

| 50STD-900F2 | UHR270A | 900 | UHR900A | 3000 |

| 50STD-1350F2 | UHR405A | 1350 | UHR1350A | 4700 |

| 50STD-1800F2 | UHR540A | 1800 | UHR1800A | 6000 |

| 50STD-2250F2 | UHR675A | 2250 | UHR2250A | 8000 |

Product lifting: